The low floor height of the low loader semi trailer plays a vital role in improving transport safety. By lowering the overall center of gravity of the equipment being carried, semi low loader trailer greatly minimizes the chances of accidents such as rollovers or collisions during sharp turns or emergency braking situations.

The semi trailer low loader is purpose-built for the long-haul transportation of oversized machinery and heavy equipment. The low loader is well-suited for use across several industries, including construction, agriculture, and industrial sectors.

One of its key structural advantages is the ultra-low center of gravity in the frame design, which offers added stability when loaded. Furthermore, the semi low loader trailer floor is manufactured with sufficient thickness to comfortably support heavy loads, ensuring safety and reliability during transportation.

Low Loader Semi Trailer for Sale in Bamako Mali

Low Loader Semi Trailer for Sale in Bamako Mali

Interested in low loader trailer? Leave a message below to get professional recommendations!

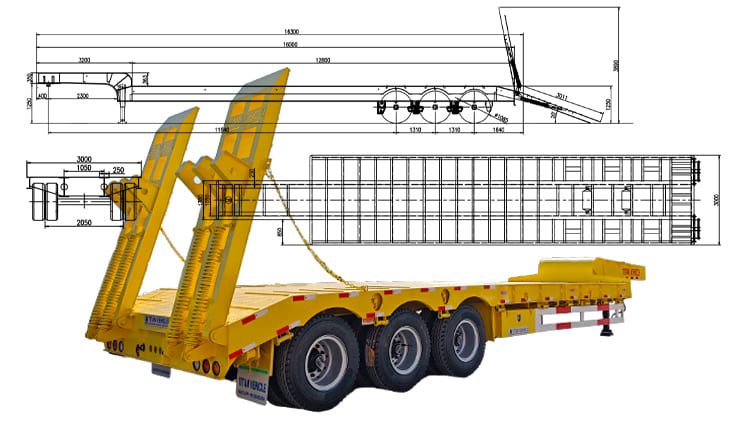

Overall Dimension: 14300mm*3000mm*1710mm

Load Capacity: 60 ton

Floor Plate: 5mm thick pattern plate

Landing Gear: 28 ton, FUWA brand

Axles: 3 axles, 13ton, TITAN brand

Tire: 12 units, 10.00R20

Ramp: 16mm thickened spring ramp

Suspension: mechanical suspension

Leaf Spring: 10 layers

Lamp: LED Lamp

Interested in low loader trailer? Leave a message below to get best quote!

The low loader floor uses a 5mm thick patterned steel plate, which creates a high-friction surface. The design feature, when combined with the anti-slip horizontal bars at the rear of the semi low loader trailer, forms a multi-layered anti-displacement structure. The configuration not only protects the machinery during loading and unloading but also helps maintain its position during travel.

In comparison to the standard 4mm floor plate, the TITAN low loader semi trailer 5mm thick plate demonstrates clear advantages in terms of both load-bearing capability and slip resistance, contributing to safer operations.

To assist with equipment loading, the semi trailer low loader includes a spring ramp system. The ramp utilizes the elastic characteristics of the spring to self-adjust and maintain smooth contact between the ramp surface and the ground. The balanced connection ensures stable loading angles.

The 16mm spring reinforcement provides robust support for heavy equipment moving onto the low loader, effectively absorbing the pressure exerted during the loading process. With a streamlined design, the ramp can be quickly deployed and requires only one operator to raise or lower, which increases operational efficiency.

Another key feature is the traction plate, which connects the semi trailer low loader to the towing truck. The TITAN semi low loader trailer uses a single, solid steel plate to construct the traction plate, ensuring that the structure remains intact under significant loads.

The 12mm thick plate is designed to resist splitting and provide consistent flexibility when connect with the tractor truck. Whether facing poor weather or rough terrain, the component maintains stable traction and effectively withstands the jolts caused by sudden braking or uneven surfaces.

Supporting the low loader semi trailer are landing gears capable of lifting up to 28 tons, with a static load capacity of 60 tons. The landing gears utilize a wide-base design, which reduces ground pressure through optimized contact surface technology.

The feature enhances the low loader semi trailer adaptability to different ground conditions, including sand, loose gravel, or muddy areas—terrain types commonly found in Mali. The well-distributed stress points allow for stable parking and loading, even in challenging environments.

To further secure heavy equipment and cargo, the rope tightener system works in tandem with the reinforced floor plate, establishing a multi-point fixing mechanism. The system is particularly effective in preventing equipment from shifting while the semi trailer low loader is in motion.

Low loader proves especially beneficial during sharp turns or sudden stops, where maintaining the equipment's position is crucial to avoid damage or accidents. As a result, the combined safety setup ensures consistent performance and the integrity of the transported goods.

Recognizing the need for corrosion protection during shipping, TITAN developed a dual-layer packaging method. Each semi trailer low loader is first coated with a layer of protective wax to guard against moisture, and then covered with a water-resistant rainproof cloth, creating a strong barrier against environmental elements.

The composite packaging solution is designed to withstand corrosive conditions such as high salt spray, commonly encountered during sea transport. Compared to traditional packaging methods, the enhanced approach offers superior protection and helps preserve the structural integrity of the semi low loader trailer throughout the delivery process.