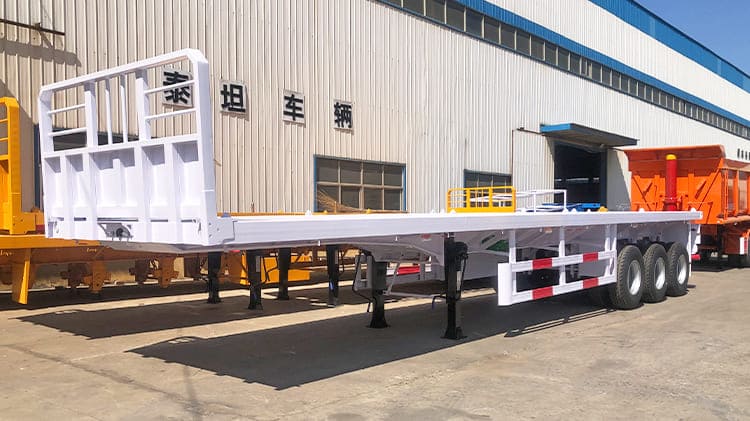

The flatbed container trailer has been carefully designed to meet regional transportation standards while delivering consistent performance for containerized and bulk cargo shipments. Its optimized construction provides operators with a trustworthy hauling solution that combines regulatory compliance with operational efficiency.

The flatbed truck trailer serves as an efficient solution for transporting standard containers by road, making particularly valuable in port operations and logistics hubs. Its widespread adoption stems from multiple advantages, including operational flexibility, simplified cargo handling, and economical running costs.

Beyond container transport, the flatbed trailer truck demonstrates remarkable versatility by accommodating various bulk commodities adaptability allows logistics operators to meet diverse freight requirements with a single equipment solution.

Flatbed Container Truck Trailer for Sale in Mali

Flatbed Container Truck Trailer for Sale in Mali

Interested in flatbed container traier? Click to get most professional recommendations!

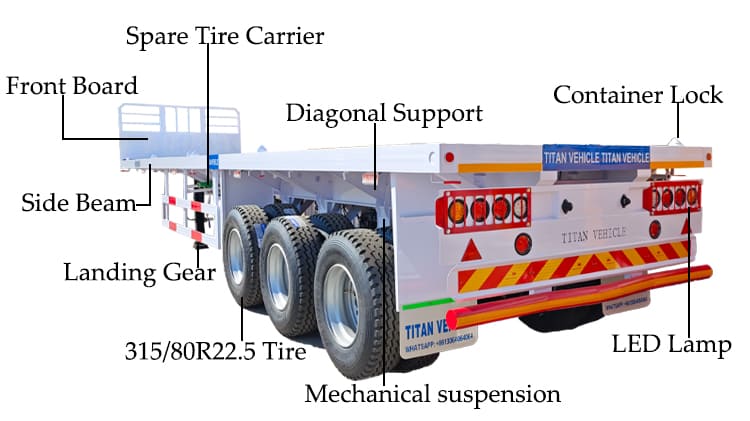

Overall Dimension: 12500mm*2500mm*1550mm

Load Capacity: 60 ton

Side Beam: 160mm high

Floor Plate: 3mm thick pattern floor plate

Trailer Feature: with front board

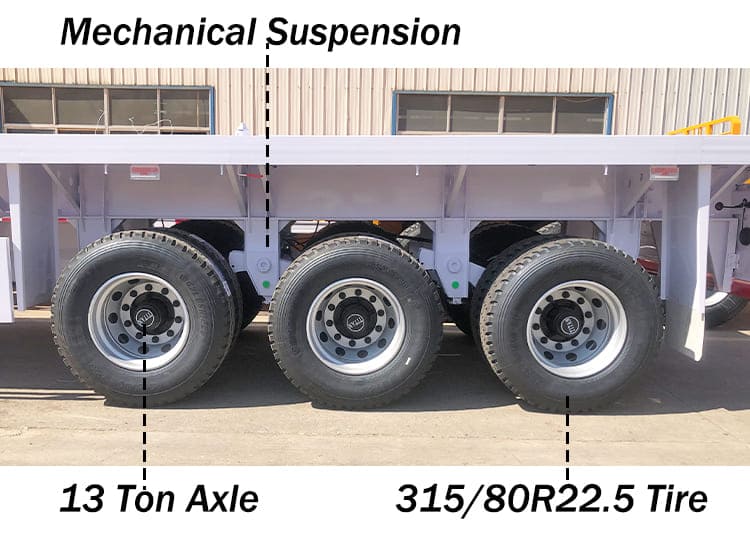

Axles: 3 axles, 13ton

Tire: 12 units, 315/80R22.5

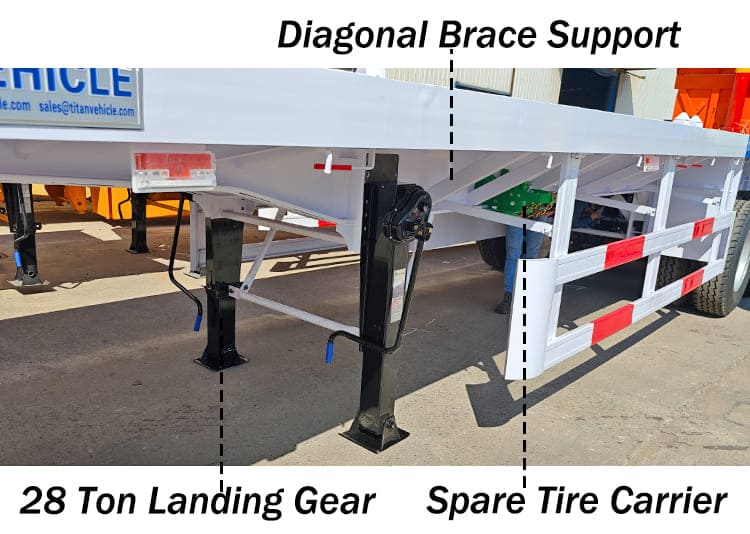

Landing Gear: 28 ton

Suspension: mechanical suspension

Leaf Spring: 10 layers

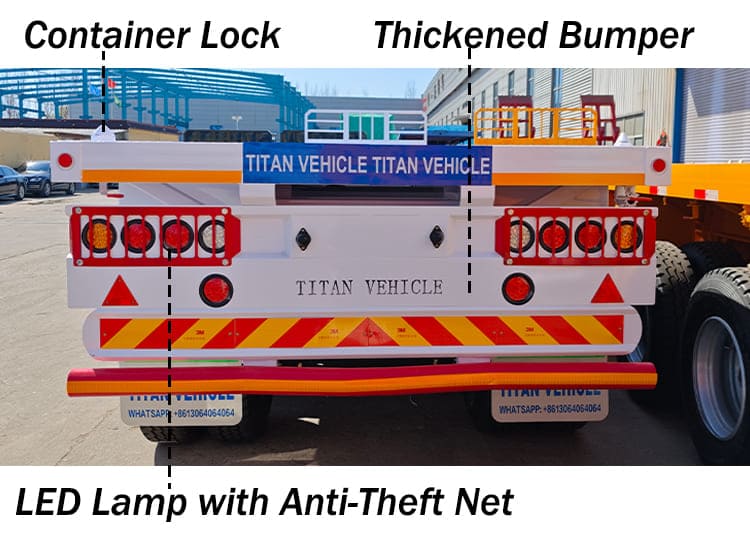

Lamp: LED Lamp with anti-theft design

Bumper: 4mm thick

Interested in flatbed container traier? Click to get most professional recommendations!

Mali buyers of TITAN flatbed truck trailer can select between two shipping methods: container transport or roll-on/roll-off (ro-ro) service. Prior to dispatch, each flatbed trailer truck undergoes a specialized protective packaging process to ensure safe delivery.

The packaging procedure begins with applying a protective wax coating to the surfaces. Subsequently, the unit is completely enclosed in a custom-fitted waterproof cover. The dual-layer protection system effectively guards against saltwater corrosion and moisture damage during ocean transit, guaranteeing the trailer arrives in pristine condition.

The TITAN flatbed container trailer adopts a carefully designed chassis structure, which firmly connects the cross beam and the main beam through diagonal bracing to form a stable overall frame.

The structural design can effectively disperse the force, and the arrangement spacing of the diagonal bracing is strictly controlled within 500 mm, which significantly improves the body's ability to resist deformation which particularly worth mentioning that the cross beam is made of channel steel with a thickness of 100 mm.

The strengthening treatment enables the flatbed trailer truck to perform well when carrying heavy objects, and both driving stability and safety are fully guaranteed.

In terms of the load-bearing system, the flatbed truck trailer is equipped with a professional-grade reinforced floor, which can maintain structural integrity even when fully loaded. The floor is made of 3 mm thick anti-slip patterned steel plate.

The design is not only beautiful and generous, but more importantly can increase the friction between the cargo and the floor, effectively preventing the cargo from sliding during transportation. The thickened floor has excellent support performance and can easily cope with complex road conditions in Mali.

The body surface adopts advanced powder spraying and baking paint technology, which has obvious advantages in anti-corrosion and anti-aging. Compared with traditional paint, powder coating has stronger adhesion and is not easy to peel off. Flatbed container trailer can maintain bright colors for a long time even in areas with strong sunshine.

Actual use shows that flatbed truck trailer treated with the process can still maintain good appearance during the five-year service life, greatly reducing the maintenance cost of users.

The power bearing system is another highlight of the flatbed trailer truck, equipped with 3 sets of 13-ton heavy-duty axles. The high-specification axle enables the flatbed truck trailer to have a load capacity of about 60 tons, which fully meets the needs of heavy-duty transportation.

The reinforced design of the 13-ton axle is particularly suitable for rugged roads in places, and can effectively resist long-term bumps and gravel impacts, avoiding safety hazards such as axle deformation.

The suspension system adopts an innovative multi-level buffer design, and the main structure is made of high-strength steel. The 70mm center balance pin and the four-sided reinforcement structure together constitute a restraint system, which performs well under harsh road conditions.

When encountering potholes, the suspension can effectively absorb vibrations and greatly reduce the impact on the cargo. The unique structural design not only ensures sufficient rigidity, so that the flatbed container trailer has minimal deformation when driving on gravel roads, but also maintains good flexibility, perfectly balancing the load-bearing performance and shock absorption effect. The application of multi-leaf spring components further improves torsional rigidity and minimizes the impact damage to the tire.